Product Description

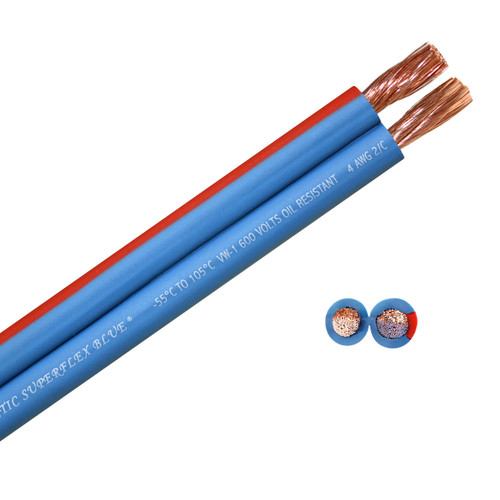

Arctic Superflex Blue®

Double Conductor Wire

4 AWG

100 Foot Spool

Legend:

4 AWG 2/C ARCTIC SUPERFLEX BLUE -55C TO 105C VW-1 600 VOLTS OIL RESISTANT

Outside Diameter: 0.80" x 0.40"

We use Arctic Superflex Blue® Double Conductor Cable exclusively in our stock and custom jumper cable systems.

Arctic Superflex Blue® has been tested and successfully used for more than a decade in the harsh environment of Alaska's Arctic North Slope. Flexibility is achieved by combining finely stranded copper construction with a jacket resistant to the abuses of oil, gasoline, acids, chemicals, salt water and sunlight. Arctic Superflex Blue® Double Conductor Wire is highly abrasion resistant and can be used in most 600 volt applications.

Features:

- Same Thermoplastic Elastomer jacket as Arctic Ultraflex Blue®

- Fine stranded, flexible copper construction for maximum conductivity

- Outstanding cold weather flexibility to -67°F (-55°C)

- High temperature performance to 221°F (105°C)

- Highly abrasion, chemical, water and sunlight resistant

- Parallel bonded construction

- Polarity stripe extruded into jacket

- Tangle resistant

- Built to same UL/AWG specifications as Arctic Ultraflex Blue®

- Exceeds Society of Automotive Engineers (SAE) standards

- Available 8 AWG through 1/0 AWG

- Other sizes available on request

- Custom colors and striping available

- Made in the USA

Applications:

- Battery and jumper cables

- Wind and solar power systems

- Outboard motor leads

- Tow truck booster systems

- ATV and RV power cables

- Uninterrupted power supply systems (UPS)

Manufactured exclusively by Polar Wire Products

Construction Specifications:

- 4 AWG

- 600 Volts

- Class K Copper Stranding (420/30) per conductor

- .240" Nominal Conductor Outside Diameter

- .080" Insulation Thickness

- 0.80" x 0.40" Minimum Finished Outside Diameter

Check out Polar Wire's

Arctic Superflex Blue® Jumper Cables and Harness Systems

The finest Jumper Cables available ANYWHERE!