Product Description

1 1/2" Dual Wall Heat Shrink Tubing

Adhesive Lined Polyolefin

48" Length

Flexible, Halogen-Free, Flame Retardant Heat Shrink

Flexible dual wall heat shrink can be used in a variety of applications and excells where environmental issues are a concern. When applying heat to shrink the tubing, the adhesive lining melts and flows to provide an excellent barrier from fluids, corrosion, and moisture. This heat shrink is useful for a variety of electrical applications.

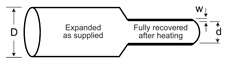

When fully recovered, the 3:1 material will shrink to one third of its original diameter. The tubing's wall thickness also changes proportionally to the degree of recovery.

Features:

- High 3 to 1 shrink ratio

- Seals and protects components from moisture and corrosion

- Good mechanical strength for protection, insulation and strain relief

- Operating temperature range: -55°C to 125°C (-67°F to 257°F)

- Minimum shrink temperature: 110°C (230°F)

Applications:

- Ideal for connector sealing, breakouts, and connector to cable transitions

- Automotive and marine wire harness bundles, and cable repair

- Covering for components and other electronics or electrical connections

- Adhesive liner bonds to a variety of materials including plastics, rubbers, and metals

- The high 3:1 shrink ratio allows repair of most damaged jackets without removing connectors

Approvals and Compliance:

- UL and CUL Recognized

- UL 224

- RoHS Compliant

- F Mark

- REACH

- VW1 Flame Retardant

- Halogen Free

![]()

![]() -55°C to 125°C

-55°C to 125°C

Sizes

Select a size which will shrink snugly over the component to be covered. Match your component diameter with the Recovered Inside Diameter (d) for the best fit. Restricted recovery will result in lower wall thickness.

| EXPANDED INSIDE DIAMETER (D) | RECOVERED INSIDE DIAMETER (d) | RECOVERED WALL THICKNESS (w) | |||||

|---|---|---|---|---|---|---|---|

| SIZE | PART NO. | inches | mm | inches | mm | inches | mm |

| 1/8 | HS-0125 | 0.142 ± .016 | 3.60 ± 0.04 | 0.039 | 1.0 | 0.033 ± 0.010 | 0.85 ± 0.25 |

| 3/16 | HS-0187 | 0.201 ± .016 | 5.10 ± 0.04 | 0.059 | 1.5 | 0.041 ± 0.010 | 1.05 ± 0.25 |

| 1/4 | HS-0250 | 0.272 ± .020 | 6.90 ± 0.05 | 0.079 | 2.0 | 0.043 ± 0.010 | 1.10 ± 0.25 |

| 3/8 | HS-0375 | 0.390 ± 0.020 | 9.90 ± 0.05 | 0.118 | 3.0 | 0.057 ± 0.010 | 1.45 ± 0.25 |

| 1/2 | HS-0500 | 0.524 ± .024 | 13.3 ± 0.06 | 0.157 | 4.0 | 0.059 ± 0.014 | 1.50 ± 0.35 |

| 3/4 | HS-0750 | 0.776 ± .028 | 19.7 ± 0.07 | 0.236 | 6.0 | 0.079 ± 0.018 | 2.00 ± 0.45 |

| 1 | HS-1000 | 1.020 ± .028 | 25.9 ± 0.07 | 0.331 | 8.4 | 0.079 ± 0.022 | 2.00 ± 0.55 |

| 1 1/4 | HS-1250 | 1.220 ± .039 | 31.0 ± 1.00 | 0.394 | 10.0 | 0.087 ± 0.022 | 2.20 ± 0.55 |

| 1 1/2 | HS-1500 | 1.614 ± .039 | 41.0 ± 1.00 | 0.539 | 13.7 | 0.098 ± 0.022 | 2.50 ± 0.55 |

| 2 | HS-2000 | 2.008 ± .039 | 51.0 ± 1.00 | 0.650 | 16.5 | 0.098 ± 0.022 | 2.50 ± 0.55 |

Specifications

| PROPERTY | TYPICAL VALUE |

|---|---|

| Shrink Ratio | >3 to 1 |

| Shrink Temperature | 110°C |

| Operating Temperature Range | -55°C to 125°C |

| Tensile Strength | ≥10.4 MPa |

| Dielectric Voltage Withstand | 600v |

| Ultimate Elongation | ≥200% |

| Radial Shrinking Ratio | ≥50% |

| Longitudinal Change | ≤15% |

| Aging in Circulating-Air Oven | 158.0±1.0°C, 168 hrs |

| Tensile Strength After Aging | ≥7.3 MPa |

| Ultimate Elongation After Aging | ≥100% |

| Dielectric Strength | ≥15kV/mm |

| Volume Resistivity | ≥1013 Ω cm |

| Flammability | VW-1 |

| Water Absorption | <0.4% |

| Fluid Resistance | Excellent |

| Adhesive Softening Point | 85±5°C |

| Adhesive Peel Strength | >80N/25mm |