Product Description

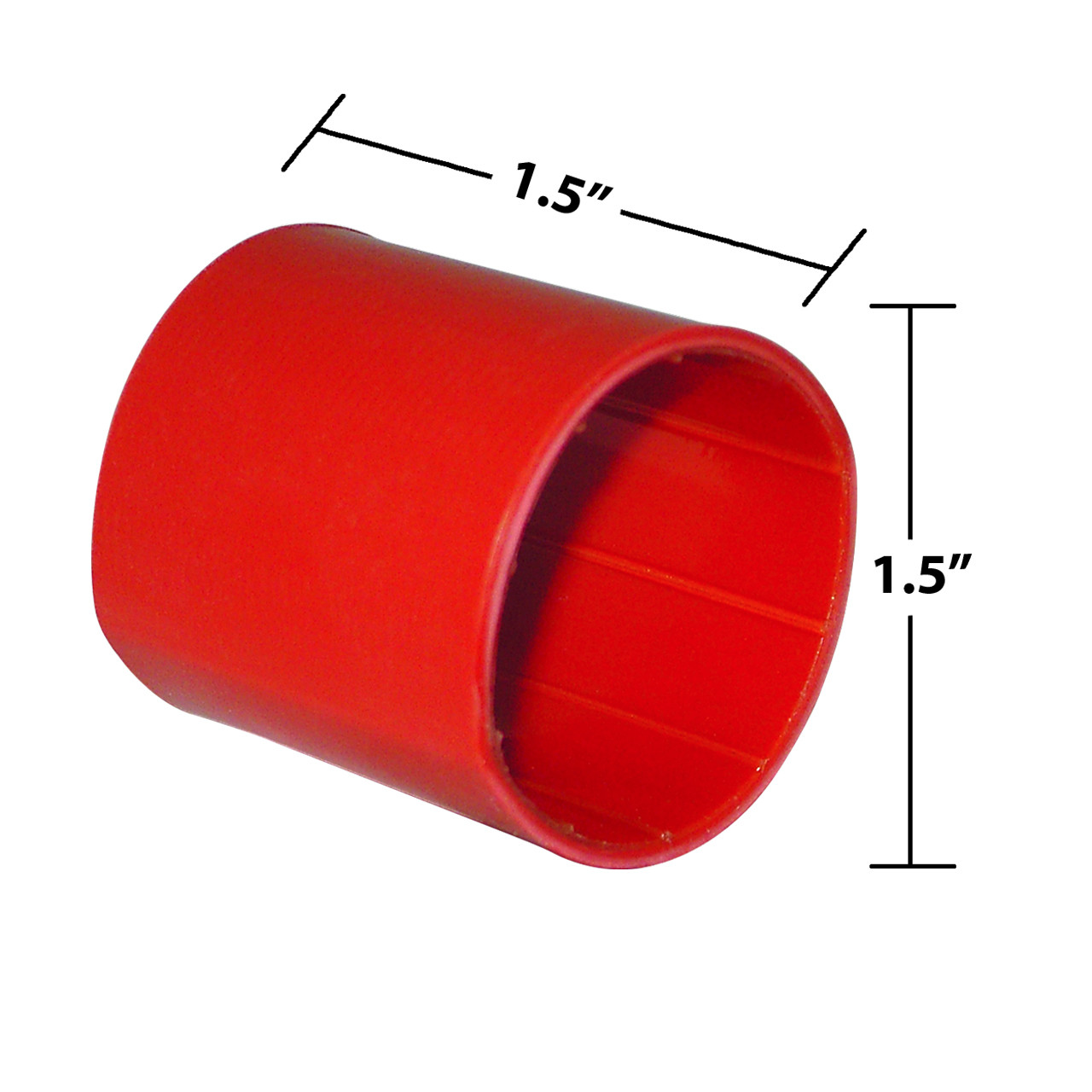

1 1/2" Heavy Wall Heat Shrink

Adhesive Lined

Crosslinked Polyolefin Heat Shrink

Red

Cut piece 1 1/2" Length

- Impact, abrasion, corrosion, and chemical resistant; suitable for submersion and direct burial

Features:

- Seals out water and dirt

- High 3 to 1 shrink ratio

- Meets UL 486D, CSA C22.2 198.2, ANSI C119-1, Western Underground Guide 2.4, 2.5, ICEA and NEMA insulation thickness requirements, DNV Type approval

- Continuous operating temperature: -55°C to 110°C

- Shrink temperature: 120°C

- 600V, 90°C continuous use

Applications:

- Electrical/Utility/Industrial

- Strain relief and mechanical protection

- Insulation of primary low voltage cables

![]() -55°C to 110°C

-55°C to 110°C

Sizes

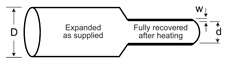

Select a size which will shrink snugly over the component to be covered. Match your component diameter with the

Recovered Inside Diameter (d) for the best fit. Restricted recovery will result in lower wall thickness.

HSREDHD-1.5

D: 1.5 in. (≥40mm)

d: .472 in. (≤12mm)

w: .158 in. (≥4mm)

Specifications:

| Physical Property | Test Method | Typical Performance |

|---|---|---|

| Tensile Strength | ASTM D412, ISO 37 |

2100 psi (14.5 MPa) |

| Elongation | ASTM D412, ISO 37 |

600% |

| Elongation after heat aging (168 hours at 175°C) |

ASTM D2671, ISO 37 |

500% (250%) |

| Longitudinal change on recovery |

ASTM D2671 | +1%, -10% |

| Specific Gravity | ASTM D792 | 1.1 |

| Heat shock (4 hours at 255°C) |

ASTM D2671 | No cracking or flowing |

| Low temperature flexibility (4 hours at -55°C) |

ASTM D2671 | No cracking or splitting |

| Hardness (Shore D) | ASTM D2240 | 50D |

| Oxygen Index | ASTM D2863 | 27.00 |

| Flammability | ASTM D2671 | Flame Retardant |

| Electrical Property | ||

| Dielectric Strength | ASTM D149 | 500 V/Mil (20kV/mm) |

| Dielectric Voltage Withstand (2500V, 60Hz, 1 min.) |

UL 486D | No breakdown, 24kV-1 Min. 15kV-4 hrs. |

| Volume Resistivity | ASTM D257 | 1016 ohm-cm |

| Chemical Property | ||

| Fluid Resistance | MIL-DTL- 23053/15 |

Good to excellent |

| Copper Corrosion | ASTM D2671 | No Corrosion |

| Water Absorption | ASTM D570 | 0.2% |

| Fungus Resistance | ASTM G21 | No growth |

| Adhesive Property | ||

| Adhesive softening point | ASTM E28 | 92°C +/- 5°C |

| Adhesive peel strength (300mm/min at 23°C) - to steel, aluminum, P.E. - to PVC |

ASTM D1000 ASTM D1000 |

35 pli 20 pli |

| Adhesive lap shear (1in./min at 23°C) |

ASTM D1002 | 125 psi (0.875 MPa) |

| Adhesive Blocking (30°C) | ASTM D1146 | No blocking |

| Adhesive water absorption | ASTM D570 | less than 0.3% |

| Water penetration | STM 706 | No penetration after 236 hrs of continuous immersion |